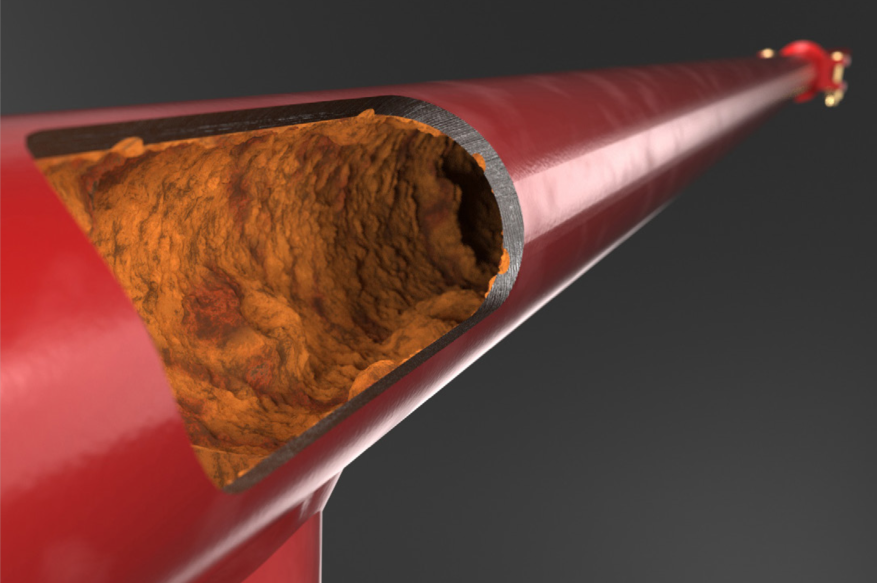

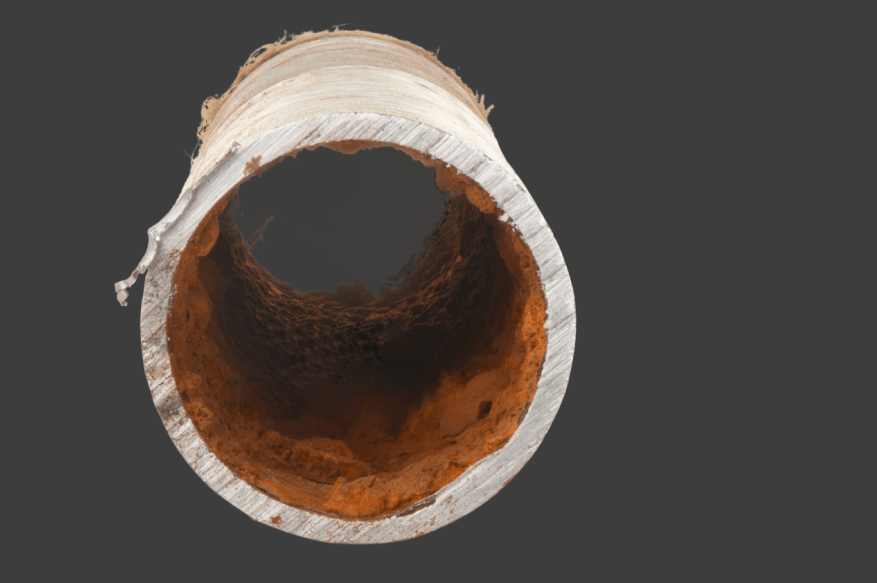

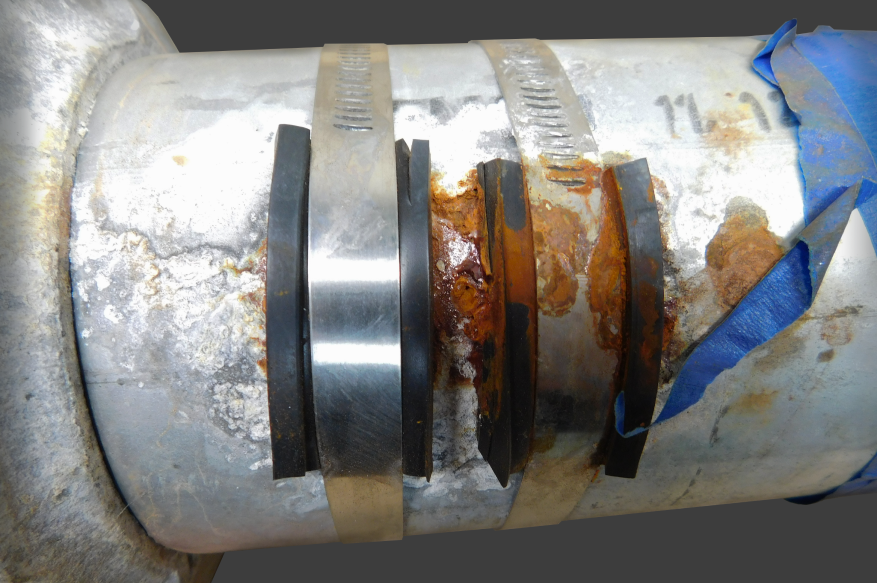

Fire pipes are the most important part of fire suppression systems. However, current fire pipes have significant disadvantages that reduce reliability.

Metallic pipes – Low corrosion and chemical resistance;

Non-metallic pipes – Low fire resistance.

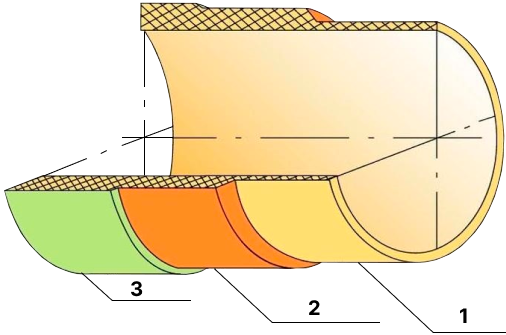

1 – The Structural layer contains radial +/- fibres (glass, basalt or carbon) with modified Epoxy matrix;

2 – The Fireproof layer contains an intumescent composition based on modified Epoxy matrix;

3 – The Outer layer – polyurethane, etc. paint.

Some application may be using The Liner (not shown here). It is also based on Epoxy matrix.

– Lightweight (easy to install)

– Environmentally friendly

– Reducing CO2 by 19% more than steel pipes

– Fire resistance (depends on thickness of fireproof layer)

– Corrosion and chemical resistance

– Operational at temperatures from -400C to +900C

– 50% greater pipe lifetime

– Decreases insurance payments

| FIRESAFE PIPE™ | METALLIC | CPVC | PP-R special | |

| Applicable according to NFPA 13 | Any | Any | Light Hazard | Light Hazard |

| Dry sprinkler system | Yes | Yes | No | No |

| Working pressure (depends of operational temperature), MPa (psi) |

1.55 - 2.48 (225-360) |

Up to 134 (19444) |

0.69 - 2.2 (100-320) |

1.2 - 2.37 (175-340) |

| Flexural modulus, GPa (psi) |

17 - 150 (2.47 x 106 - 21.76 x 106) |

70 - 200 (10.15 x 106 - 29.00 x 106) |

2.9 (4.23 x 105) |

1.6 (2.32 x 105) |

| Operational temperature |

-400C to +900C (-400F to +1940F) |

-700C to +4250C (-940F to +7970F) |

+20C to +500C (+350F to +1200F) |

+20C to +500C (+350F to +1200F) |

| Halogen free | Yes | Yes | No | Yes |

| Chemical and corrosion resisrance (depends of operational temperature) | High | Low | High | High |

| Conductive |

Yes (fireproof layer) |

Yes | No | No |

| Weatherproof | Yes | Yes | No | No |

| Types of Pipe Joints | Grooved, adhesive | Flanged, grooved, welded, etc. | Solvent cement | Hot melt, electrofusion |

| Service Life | 15-30 years | Carbon steel 10-15 years Copper, stainless steel 30-50 years | up 50 years | up 50 years |